Delivering Quality While Championing Safety & Environmental Responsibility

As a leading specialist in use of Perchloroethylene Solvent metal degreasing technology, Midland Deburr & Finish has become a key partner for the aerospace and automotive industries, meeting their rigorous demands for precision cleaning and ensuring compliance with complex regulations.

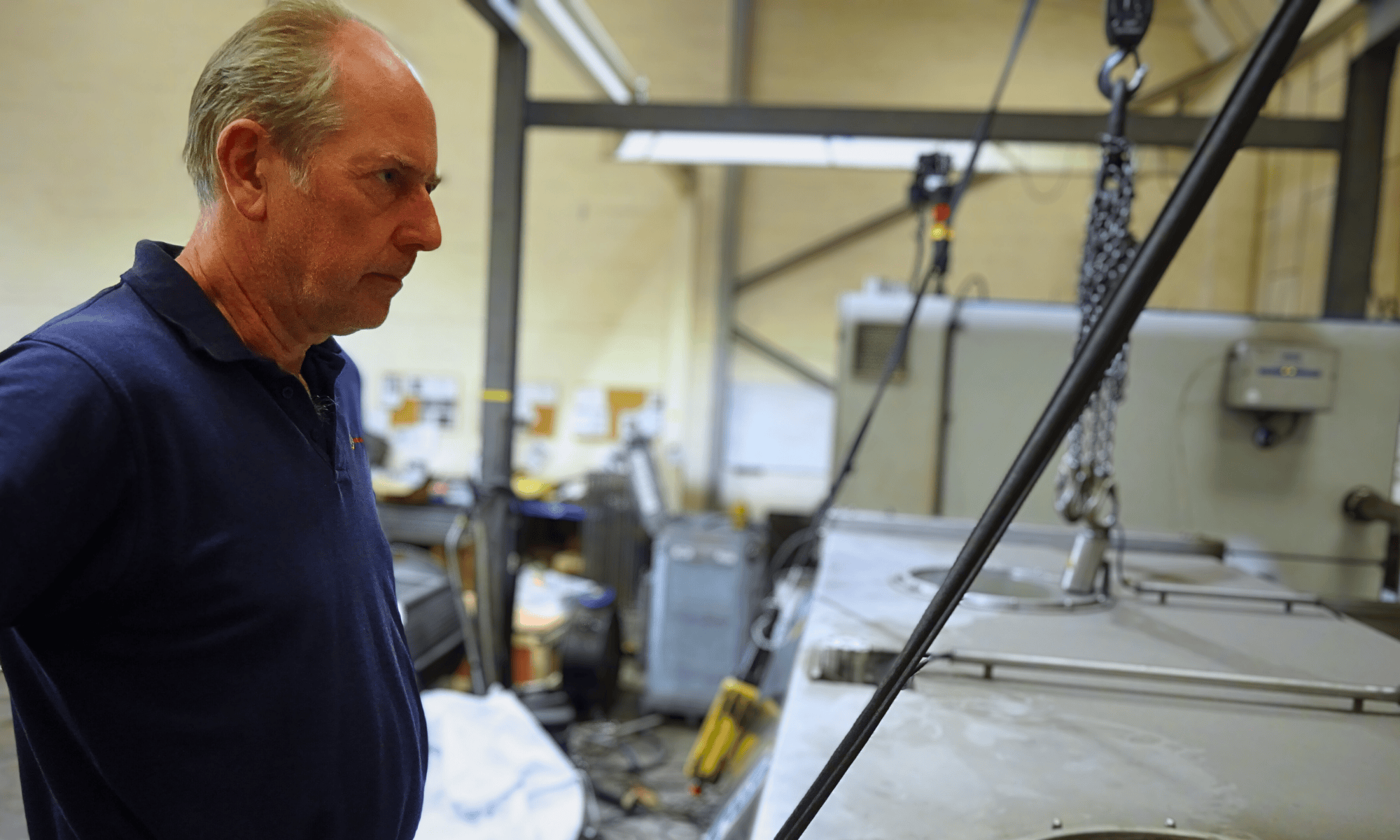

With a state-of-the-art SED-compliant vapour solvent degreaser, Midland Deburr & Finish is capable of handling components up to three metres in length and weighing as much as 500 kilograms. This advanced system ensures that metals are immaculately cleaned and dried to the exacting standards required by critical sectors. Managing Director Chris Arrowsmith highlights the effectiveness of Perchloroethylene, particularly for aerospace applications, where cleanliness and precision are paramount. “Perchloroethylene remains one of the most effective solvents for metal degreasing, especially for aerospace components where precision and cleanliness are non-negotiable. Our closed-loop vapour degreasing process not only delivers outstanding results but also minimises environmental impact, which is vital in today’s regulatory environment,” he explains.

Operating within the framework of stringent environmental and workplace safety laws, including the Industrial Emissions Directive (IED), the Health and Safety at Work Act (HASAWA), and Occupational Exposure Limit (OEL) standards, Midland Deburr & Finish ensures full compliance with emissions controls, solvent loss limits, and operator safety requirements. Arrowsmith emphasises the importance of adhering to these measures, saying, “Compliance with these standards is not optional; it’s a responsibility we take very seriously. From implementing carbon abatement measures to meticulously monitoring occupational exposure levels, we are committed to maintaining a safe workplace and reducing our ecological footprint.”

The company plays a crucial role in supporting the aerospace industry’s exacting standards, with its Perchloroethylene vapour degreasing processes preparing components for thermal processing and enhancing their metallurgical integrity and performance longevity. Arrowsmith underlines the importance of this work, stating, “Our Perchloroethylene degreasing capability is an integral part of our service, particularly for aerospace customers, where contamination-free surfaces are critical. By combining cutting-edge technology with decades of expertise, we deliver solutions that align with the highest quality standards.”

To demonstrate the value of its solvent degreasing services, Midland Deburr & Finish offers free trials to customers across various industries. This provides clients with the opportunity to experience the advantages of the method firsthand, especially for materials like aluminium that require meticulous cleaning. “Our customers trust us not only for our technical expertise but also for our ability to innovate and adapt to their evolving needs,” says Arrowsmith. “By investing in advanced equipment and sustainable practices, we ensure we remain at the forefront of metal finishing excellence.”

The company’s vapour degreasing process employs a closed-loop system that continuously recycles the solvent, improving efficiency and reducing waste. This innovative approach reflects Midland Deburr & Finish’s dedication to sustainable operations and environmental responsibility. Arrowsmith concludes, “As we look to the future, our focus remains on balancing quality with sustainability. By adhering to strict environmental and safety standards, we’re not only protecting our workforce and the planet but also delivering the reliability and precision our customers depend on.”

Through its steadfast commitment to innovation, quality, and sustainability, Midland Deburr & Finish Ltd is setting a benchmark for the metal finishing industry, cementing its position as a trusted partner for aerospace and automotive manufacturers alike.

Quick Contact Form