How Midland Deburr & Finish Supports Manufacturers

Modern manufacturing demands precision, and finishing processes like deburring and degreasing are critical to ensuring the quality, reliability, and performance of components. However, these highly specialised operations require skilled expertise, advanced technology, and continuous investment in training—resources that many manufacturers struggle to allocate.

Midland Deburr & Finish Ltd is bridging this gap by offering manufacturers an expert outsourcing solution, eliminating the need for them to invest in costly equipment, specialised training, and skilled staff. By taking on the responsibility of precision finishing, Midland Deburr & Finish allows manufacturers to focus on their core production while ensuring their components meet the highest standards of quality and performance.

The True Complexity of Deburring & Degreasing

Deburring and degreasing is fundamental to the functionality and longevity of precision-engineered parts. Deburring ensures that sharp edges and micro-imperfections are smoothed out, preventing defects that could impact performance or safety. Degreasing, particularly through advanced vapour and solvent techniques, removes contaminants that can compromise adhesion, coatings, or the mechanical integrity of critical components.

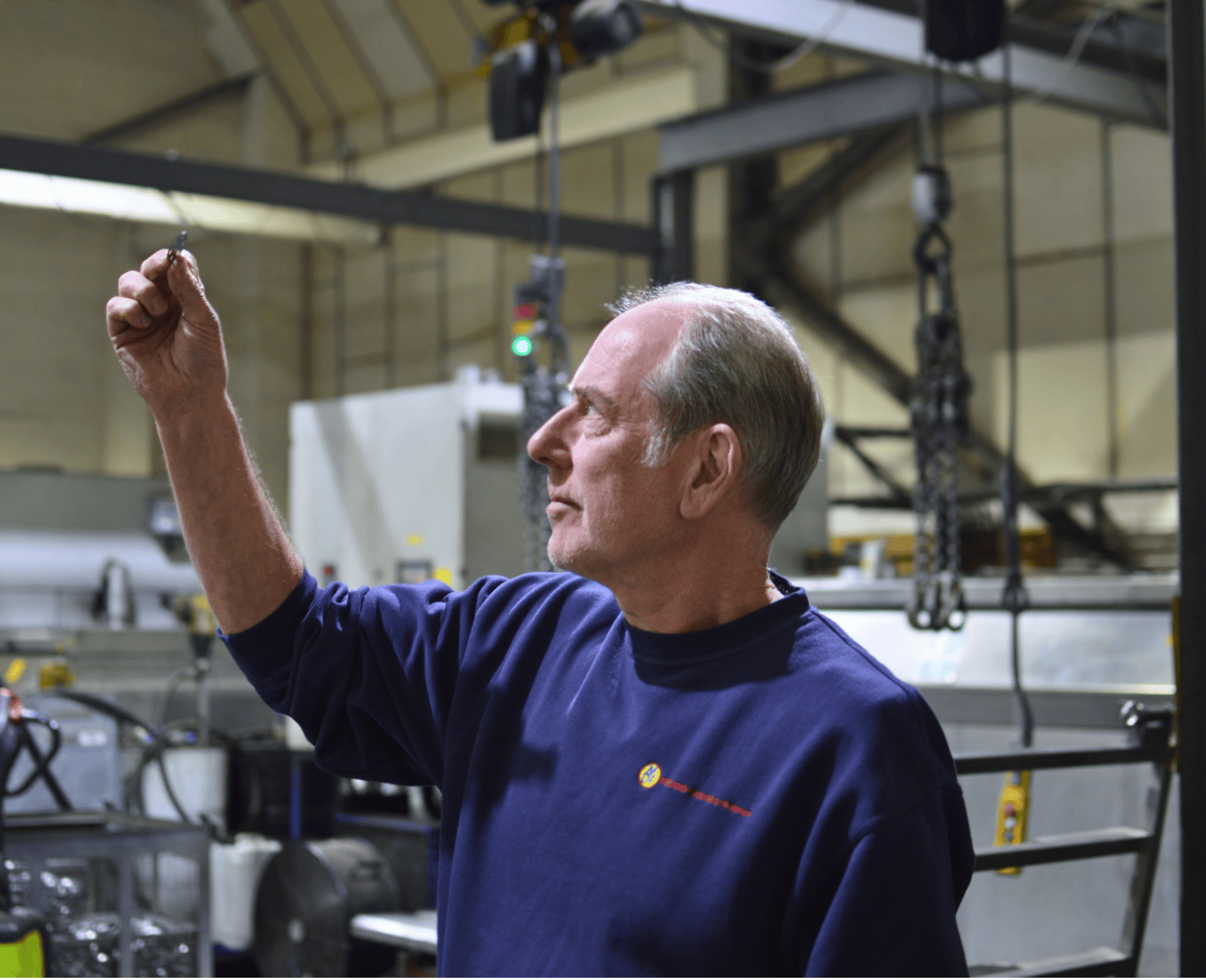

“These processes are essential in modern manufacturing,” explains Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “But they require significant expertise, and that’s where we step in—so our customers don’t have to divert their resources away from their core operations.”

Bridging the Skills Gap with Outsourcing

As the manufacturing sector faces an increasing shortage of skilled labour, many companies struggle to maintain the expertise needed for precision finishing. Investing in plant, training, and retention of specialist staff can be both costly and time-consuming.

Midland Deburr & Finish addresses this challenge by providing a fully outsourced solution, where manufacturers can rely on experienced professionals without having to manage in-house finishing operations. This approach not only reduces overhead costs but also ensures consistent, high-quality results without the burden of recruiting and training skilled finishing staff.

Advanced Techniques for Modern Manufacturing

Midland Deburr & Finish has refined its expertise across a wide spectrum of finishing processes, from vibratory and centrifugal deburring to vapour and solvent degreasing. Their specialist knowledge extends to working with complex geometries, delicate materials, and emerging technologies such as additive manufacturing.

“With 3D-printed components, for example, we’re preserving its innovation,” says Arrowsmith. “Our role is to enhance performance without compromising the design or functionality.”

A Reliable Partner for Manufacturers

By offering a comprehensive subcontract vibratory finishing service with pickup and delivery, Midland Deburr & Finish helps manufacturers overcome bottlenecks and maintain production efficiency. Clients benefit from guaranteed precision without the need to invest in expensive in-house equipment or the ongoing costs of maintaining a skilled workforce.

For new customers, Midland Deburr & Finish provides free trial runs to showcase the quality of their finishing services. “We want manufacturers to see firsthand the difference expert finishing makes,” Arrowsmith notes. “Every detail matters to us, from preventing impingement damage to ensuring the most efficient drainage systems. It’s about delivering excellence every time.”

The Strategic Advantage of Expert Outsourcing

As the industry evolves and the demand for precise finishing grows, Midland Deburr & Finish is proving that outsourcing is a cost saving as as well as a strategic advantage. Their expertise ensures that manufacturers can continue to innovate without the added complexity of managing in-house finishing operations.

“At Midland Deburr & Finish, we believe that attention to detail has the greatest impact,” Arrowsmith concludes. “Our mission is to ensure that every component we handle meets the highest standards of quality and performance, allowing our clients to focus on what they do best—manufacturing excellence.”

With over 25 years of experience, Midland Deburr & Finish continues to be a trusted partner for manufacturers, turning finishing challenges into competitive advantages.

Quick Contact Form