Midland Deburr & Finish Champions 'Buy British' as Shield Against Global Economic Headwinds

In an era of increasing global economic uncertainty and the looming threat of adverse trade tariffs, one Midlands-based manufacturing specialist is advocating for a renewed focus on domestic sourcing and production: Midland Deburr & Finish Ltd. With a 25-year history as a cornerstone of the UK subcontract finishing industry, the company believes that embracing a ‘Buy British’ ethos can provide a robust defence against volatile international markets.

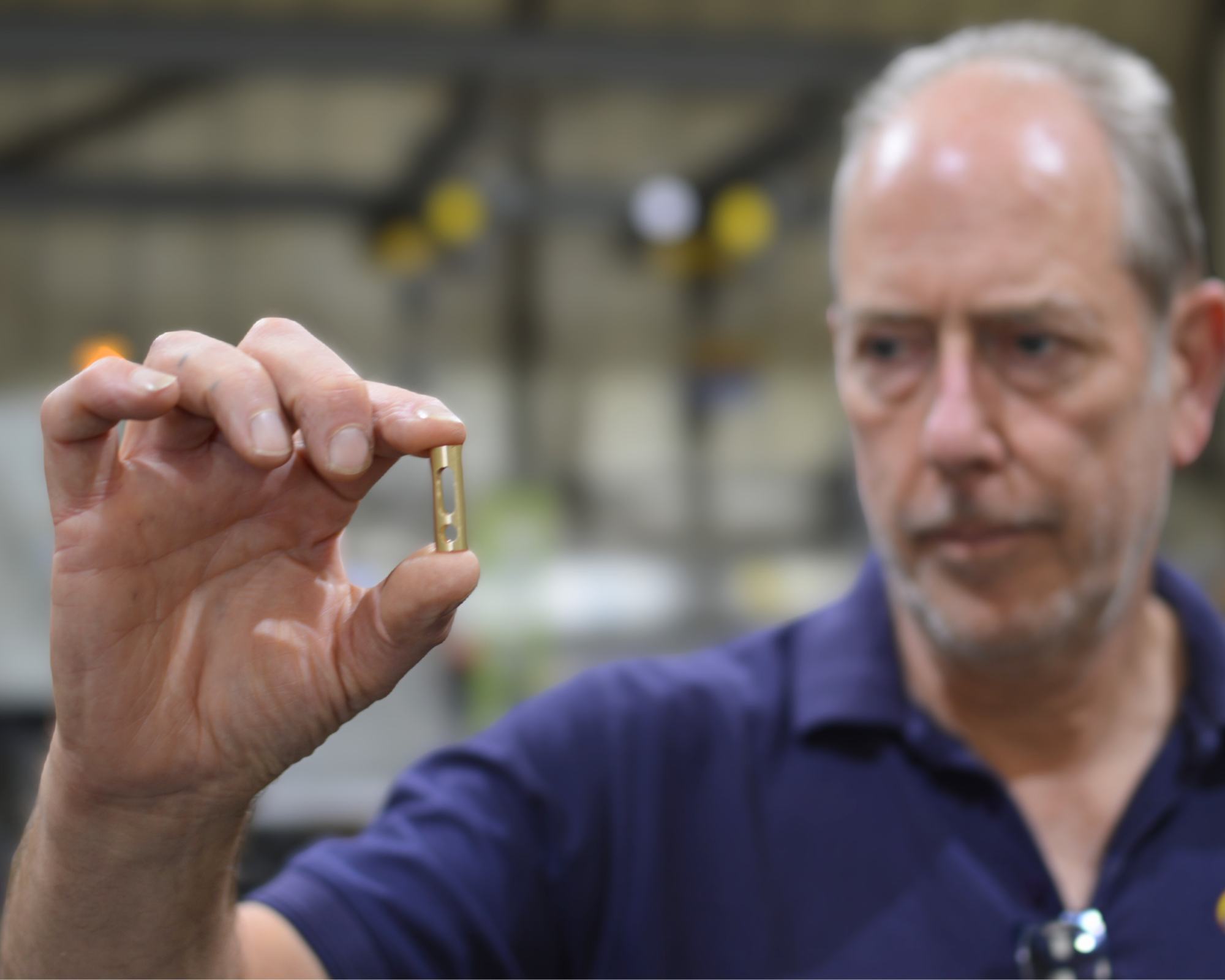

Established in 1999, Midland Deburr & Finish has built a strong reputation as a "one-stop shop" for metal degreasing, vibro deburring, solvent degreasing, vapour degreasing, barrelling, and casting impregnation. Serving a diverse clientele across the automotive, aerospace, Formula One, and general engineering sectors, the company prides itself on its commitment to quality and environmental sustainability.

According to Chris Arrowsmith, Managing Director of Midland Deburr & Finish, the concept of prioritising British suppliers and manufacturers has never been more relevant. "In these uncertain times, relying on complex international supply chains can introduce significant risks," he might argue. "Embracing 'Buy British' offers a pathway to greater stability, allowing us to support our national economy, reduce reliance on potentially volatile overseas markets, and minimise the impact of disruptive trade tariffs."

Midland Deburr & Finish’s own operational philosophy aligns strongly with this sentiment. As a privately-owned company based in the Midlands, they emphasise building strong relationships with their customers and providing a personal, friendly service. Their commitment to investing in process capacity and enhancing quality systems ensures they can meet the stringent requirements of their diverse customer base. This dedication to local manufacturing and service provision underpins their belief in the strength of the British engineering sector.

"When manufacturers choose to source and process components domestically, they are not just investing in a transaction; they are investing in British jobs, British innovation, and the resilience of our manufacturing infrastructure. This creates a more secure and predictable environment for businesses, insulating us to a degree from the shocks of the global economy."

The company’s comprehensive service offering reflects a commitment to supporting a wide range of manufacturing needs within the UK. From efficiently removing burrs using their diverse range of Vibratory finishing and Barrel Mass Finishing Machines to providing specialist solvent and vapour degreasing with state-of-the-art, hermetically sealed machines, Midland Deburr & Finish offers critical surface improvement solutions. They have even adapted to environmental regulations by transitioning from Trichloroethylene to Perchloroethylene in their degreasing processes. Their expansion into casting impregnation, including pre-treatment with compliant solvent degreasing and oven dehydration, further demonstrates their commitment to providing comprehensive solutions within the UK.

The benefits of a ‘Buy British’ approach, as championed by Arrowsmith, extend beyond economic stability. Reduced transportation costs, shorter lead times, and the ability to more easily ensure quality control are all tangible advantages of working with local suppliers. "Adverse trade tariffs can significantly increase the cost of imported components and services. By prioritising British partners, we can mitigate these financial burdens and maintain competitive pricing for our customers."

By championing domestic sourcing and their own commitment to quality British manufacturing, Midland Deburr & Finish position themselves as a reliable partner for companies seeking to weather economic uncertainty and potential tariff barriers. Their long-standing presence and comprehensive service portfolio underscore the strength and capability of the UK’s subcontract manufacturing sector.

Quick Contact Form